The production difficulty of monofilament nylon fishing nets is so great, which involves many factors, including material characteristics, manufacturing process, structural design, quality control, and environmental protection. This article will explore these factors and explain why manufacturing monofilament nylon fishing nets is a challenging task.

Material characteristics

Nylon is a synthetic polymer commonly used in the production of fishing nets due to its excellent strength, wear resistance, and chemical corrosion resistance. However, the production of nylon requires highly precise chemical reaction conditions. The following are some main material characteristics considerations:

a. Physical property control: The physical properties of nylon, such as molecular weight, molecular arrangement, and molecular structure, need to be strictly controlled. Even small changes can lead to differences in the performance of monofilaments.

b. Consistency: It is crucial to ensure that the quality and specifications of each filament are the same. The unevenness between monofilaments may lead to the unevenness of the entire fishing net, thereby reducing its performance.

c. Ductility: Nylon monofilament must have appropriate ductility to have the required elasticity during fishing, while also maintaining sufficient strength to withstand the pulling force during the capture process.

manufacturing process

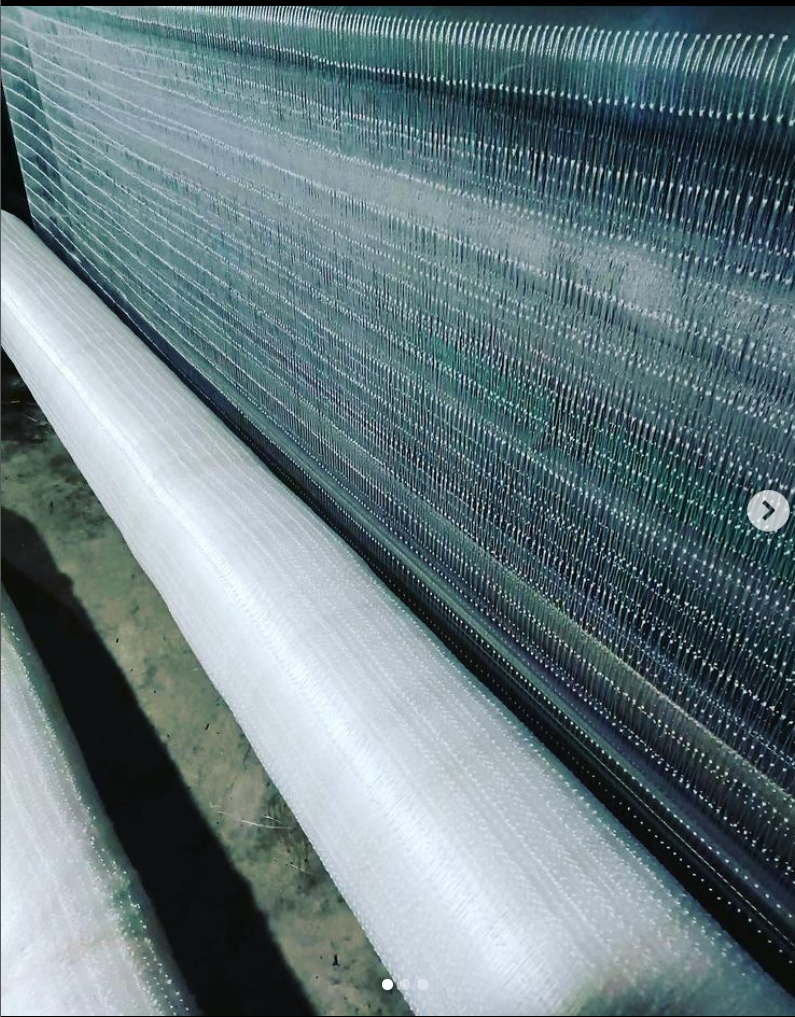

The manufacturing of monofilament nylon fishing nets involves the processing and assembly of materials, requiring highly precise equipment and technology to ensure the uniformity and stability of the fine filaments. The following are some key considerations related to manufacturing processes:

a. Preparation of filaments: Nylon particles must undergo chemical reactions and physical processing to form filaments. This step requires controlling temperature, pressure, and chemical formula to ensure the quality of the fine filaments.

b. Weaving and weaving: Manufacturing fishing nets requires weaving or combining fine threads into a mesh. This requires highly precise mechanical equipment to ensure the uniformity and strength of the grid.

c. Combination technology: Monofilaments typically need to be fused or combined to form different parts of a fishing net. This step requires ensuring the strength and stability of the bonding point to avoid damage.

Structural design

The structural design of fishing nets must consider multiple factors, including the size of the fishing target, the size of the fishing net, the size of the mesh, and the fishing environment. Different types of fishing nets require different structural designs, which require in-depth research and experience.

a. Mesh design: The mesh design of fishing nets needs to consider the size of the target species. A large mesh size may cause small fish to escape, while a small mesh size may capture non target species.

b. Strength and Durability: Fishing nets must have sufficient strength and durability to cope with various stresses of capture and towing. This requires appropriate wire diameter and mesh design.

c. Fluid dynamics: The design of fishing nets also needs to consider water flow and marine environment to ensure that the nets have good fluid dynamics performance during use.

quality control

The process of manufacturing monofilament nylon fishing nets requires strict quality control to ensure consistency in the quality of each monofilament and the entire fishing net. Any inconsistency may reduce the performance and lifespan of fishing nets.

a. Testing and Inspection: Each single filament and fishing net made of it needs to be tested and inspected to ensure that it meets specifications and standards.

b. Defective product handling: Any non-conforming monofilament or fishing net must be properly handled or repaired to ensure the quality of the final product.

c. Quality standards: The manufacturing process needs to follow a series of quality standards and guidelines to ensure the performance and reliability of fishing nets.

Environmental issues

The production process of nylon may involve some environmental issues, including wastewater discharge and waste treatment. Therefore, environmental measures need to be taken to reduce the negative impact on the environment when producing monofilament nylon fishing nets. This may include wastewater treatment, material recycling, and reducing energy consumption.

In summary, the reason why the manufacturing difficulty of monofilament nylon fishing nets is so high is because it involves multiple complex aspects, from controlling material properties to precision requirements of manufacturing processes, and then to multiple factors such as structural design, quality control, and environmental protection. Only through a high level of technology and strict management can high-quality nylon fishing nets be produced to meet the needs of the fishing industry. This also makes manufacturing monofilament nylon fishing nets a challenging and technically challenging task.